Protection Devices for Canned Motor Pump (TRG/THG)

Protection device to ensure safe operation of TEIKOKU canned motor pumps.

TRG has become TEIKOKU's signature protection device in Teikoku canned motor pumps through its outstanding field service over 50 years.

- Field

- Others

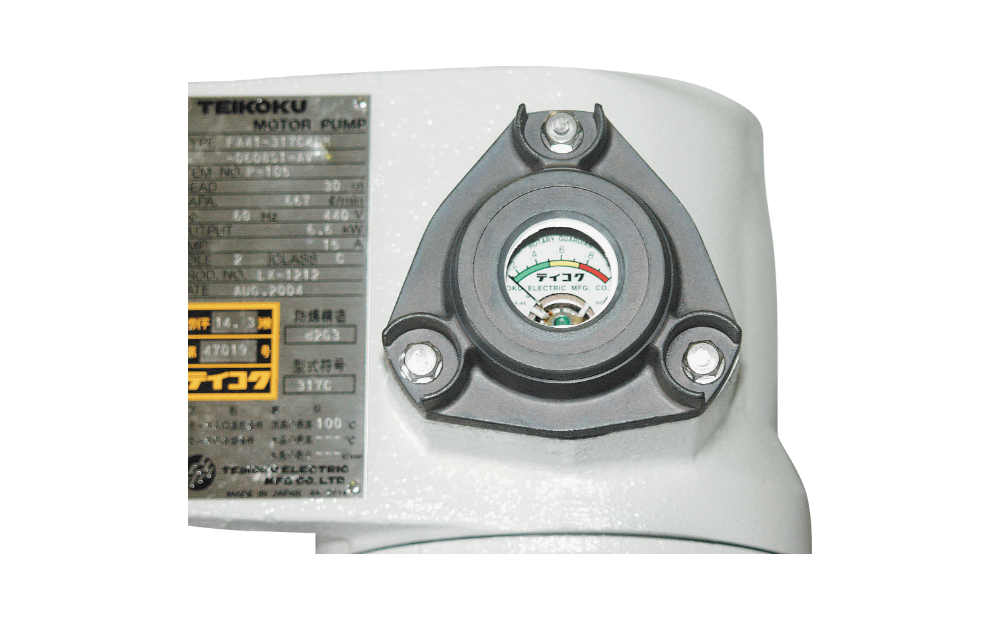

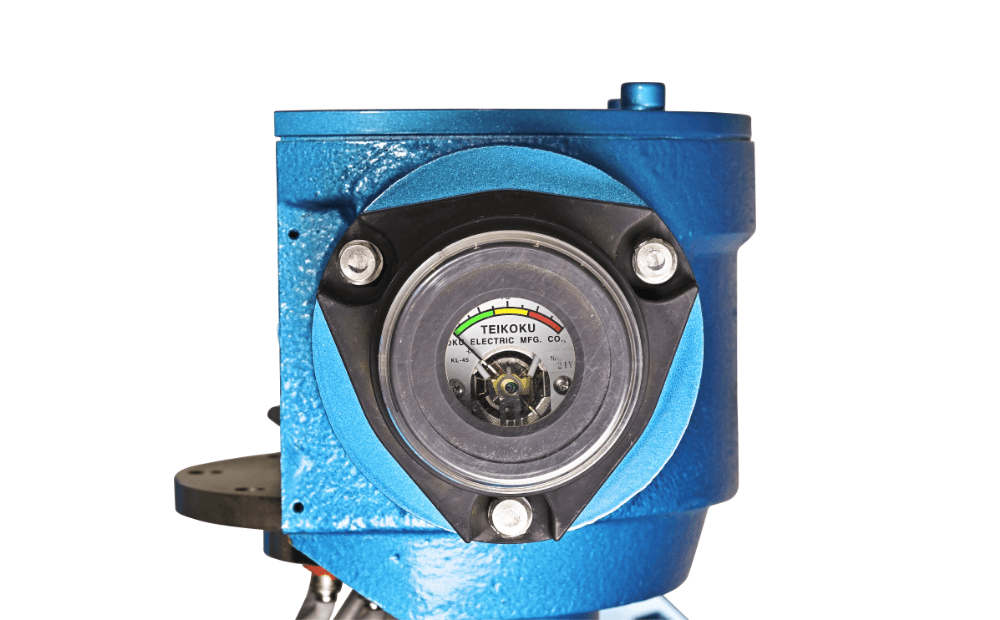

TRG (Teikoku Rotary Guardian)

TRG displays the real-time bearing wear state in the radial direction of the canned motor pump bearings.

TRG makes it possible to monitor the bearing wear state constantly without disassembling and inspecting the bearings, helping schedule the maintenance, inspection, and overhauling the canned motor pump before mechanical damage occurs.

All canned motor pumps are equipped with TRG as standard.

The device electrically detects the following abnormalities during operation:

- bearings' radial abrasion level of canned motor pump

- open-phase motor, short-circuited motor

- reverse rotating motor (option)

Remote monitoring is also available.

In addition to on-site monitoring of canned motor pump TRG can also be used for remote monitoring by using an optional panel meter.

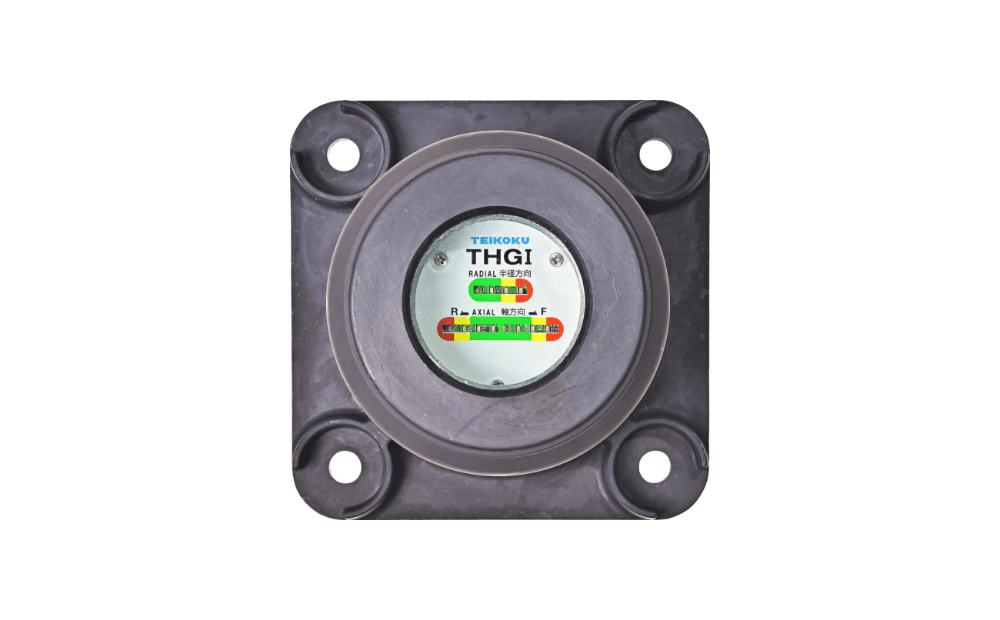

THG (Teikoku Hybrid Guardian) Option

THG displays the real-time bearing wear state not only in the radial direction but also in the axial direction of the canned motor pump bearings.

THG can display the detected bearing wear state through a series of LED lights.

THG is optional.

Other options

TRG Converter

TRG Converter converts the TRG signal (0 to 1 Vrms) into a 4-20 mA signal or 1-5 VDC signal.

Remote monitoring is achieved by connecting the output signal of the converter to customer equipment such as DCS or remote display.

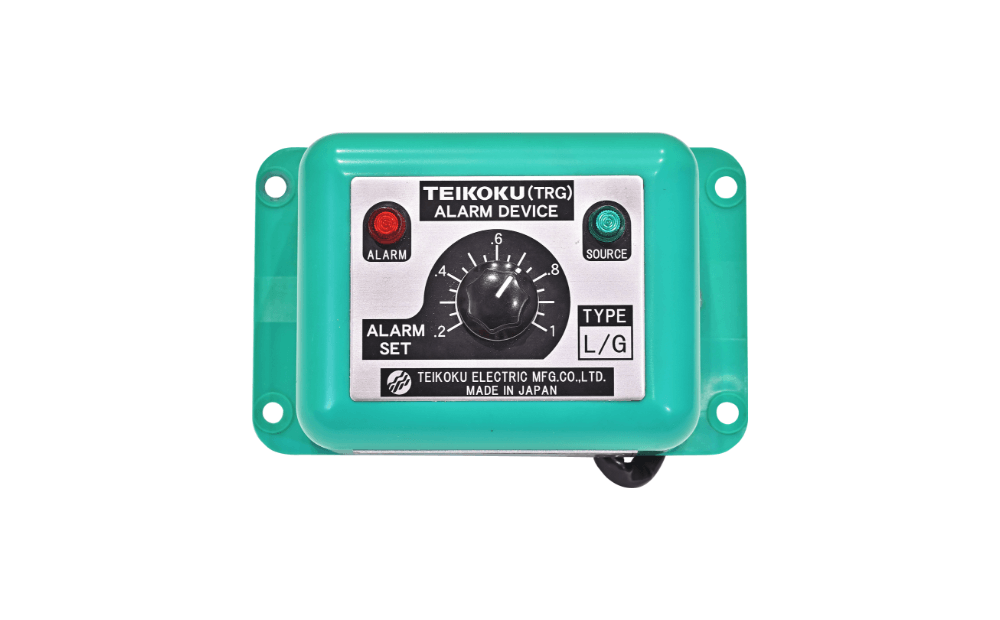

TRG Alarm Device

TRG Alarm Device outputs a relay contact signal when the TRG level exceeds the set value.

The output from the alarm device can be connected to alarm buzzers and to power supply trip circuit to stop the pump.

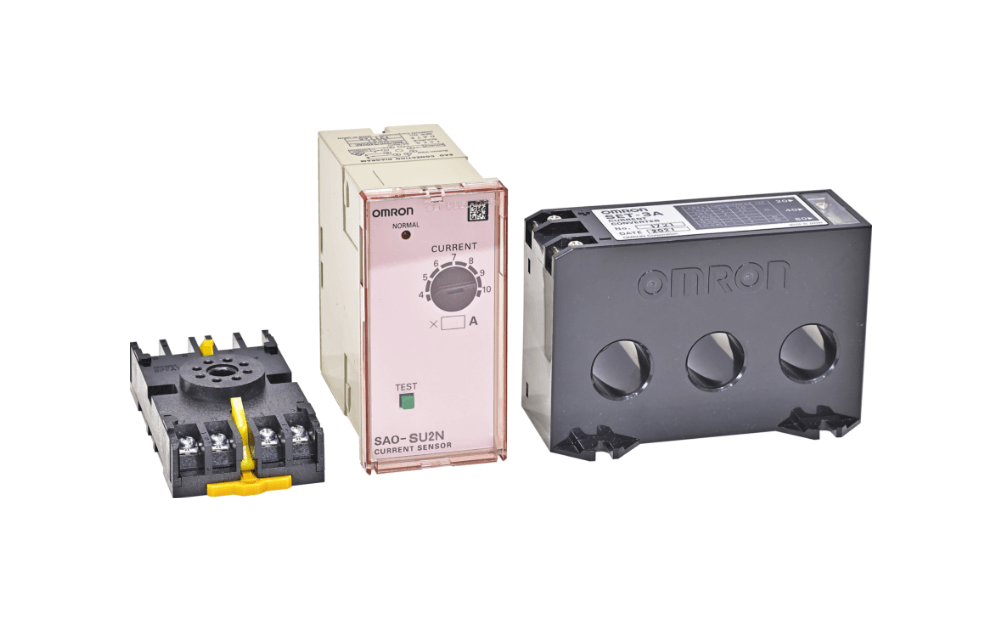

Low Current Relay (SE Relay)

Continued operation under dry running condition will cause abnormal wear and seizure of sliding parts (bearings, sleeves, thrust collars), resulting in the pump failure.

The SE relay detects increase in motor current and outputs a relay contact signal that is used to activate the pump trip circuit, thus preventing catastrophic pump failure.